CNC Engineering Plastic PE Accessories

- These parts are custom made only, not in stock; We can produce based on your drawings or samples. - We can sign NDA(No

Description

Basic Info.

| Model NO. | CNC |

| Origin | Guangzhou, China |

| HS Code | 3926909090 |

| Production Capacity | 10000PCS |

Product Description

| Property | Item No. | Unit | POM-C | POM-H | POM-H+PTFE | |

| Mechanical Properties | 1 | Density | g/cm3 | 1.41 | 1.43 | 1.50 |

| 2 | Water absorption(23ºCin air) | % | 0.20 | 0.20 | 0.17 | |

| 3 | Tensile strength | MPa | 68 | 78 | 55 | |

| 4 | Tensile strain at break | % | 35 | 35 | 10 | |

| 5 | Compressive stress(at 2%nominal strain) | MPa | 35 | 40 | 37 | |

| 6 | Charpy impact strength (unnotched) | KJ/m 2 | ≥150 | ≥200 | ≥30 | |

| 7 | Charpy impact strength (notched) | KJ/m 2 | 7 | 10 | 3 | |

| 8 | Tensile modulus of elasticity | MPa | 3100 | 3600 | 3200 | |

| 9 | Ball indentation hardness | N/mm 2 | 140 | 160 | 140 | |

| 10 | Rockwell hardness | - | M84 | M88 | M84 | |

- We can sign NDA(Non-disclosure Agreement) with you if you need;

- Supplying Capacity: 100,000pcs monthly; Small orders are welcome

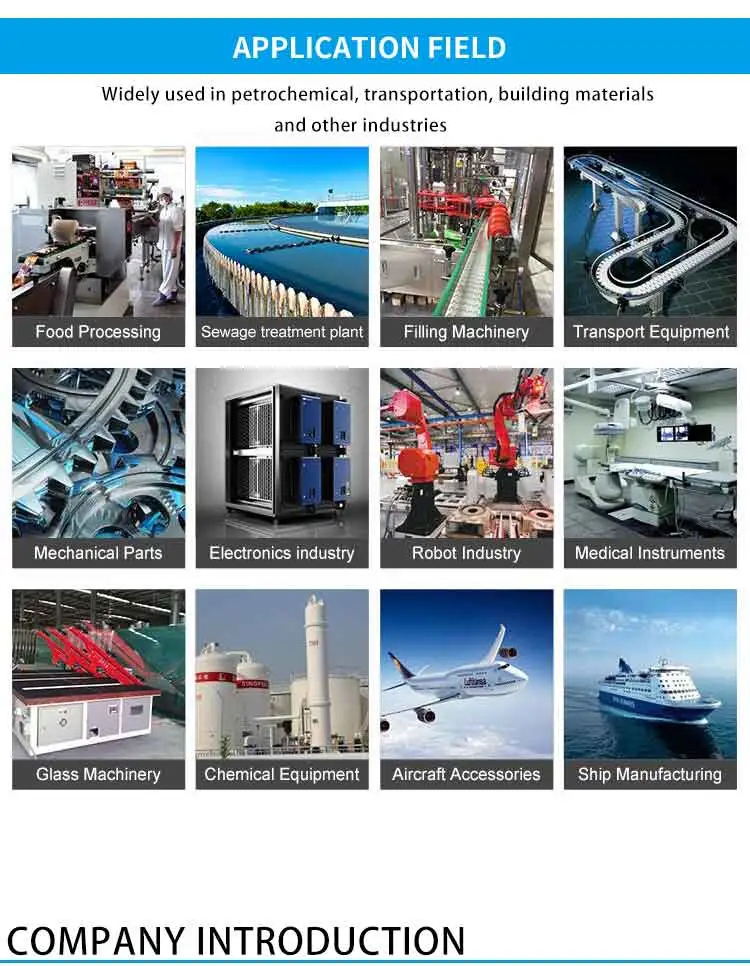

have technology and experiences in engineering plastic industry for morethan 15 years! Our company is located in

Huangpu District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for

manufacture, design, research and development ability, support personalized customization. We have full set of high

efficiency producing equipment and advanced numerical control machines, such as: molding injection machines, CNC

molding manufacture machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds

ofEngineering plastics products according to our customers'drawings or samples. Such as:

A1. Yes

Q2. What is the accuracy of the products processed by the drawings?

A2. Different equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What are your processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, moldin

machine

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company's certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen, electroplating, etc.

Prev: Diamond Core Drill Bits 76mm for Granite Stone Dry Drilling Tools Hole Saw China Factory 5/8

Next: Tungsten Carbide Taper Drill Button Bit for Stone Quarrying

Our Contact

Send now