Plastic Electronic Internal Mold Parts Automatic Infrared Thermometer Shell Injection Molding

Factory custom plastic injection molding other plastic products customized plastic injection moulding Guangdong Engineer

Description

Basic Info.

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | TS16949, CE, ISO, FDA |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | Contact Customer Service to Learn More |

| Specification | ome |

| Trademark | enqi |

| Origin | Guangzhou |

Product Description

Factory custom plastic injection molding other plastic products customized plastic injection mouldingGuangdong Engineering Plastics Industries (Group) Co. Ltd. We have the professional engineer teams and sales teams, and we have technology and experiences in engineering plastic industry for more than 15 years! Our company is located in Huangpu District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design, research and development ability, support personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines,such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics products according to our customers'drawings or samples.

1. TOL ERANCE +/-0.01MM 2. 24 HOURS ONE-ON-ONE PROFESSIONAL ANSWER3. 15 YEARS SENIOR ENGINEER 4. 3 MINS QUOTES5. ONLY 20 DAYSTO MAKE THE MOULDS 6. LISTED GROUP7. ACCURACY CAN BE DONE IN MICRONLEVEL (0.001MM) 8. MOQ: 1PCS9. REASONABLE PRICE

Mould

High precision/Factory priceUse 3D prototype printing, DFM and Moldflowanalysis! We have 4-axis and 5-axis CNCmachines, wire EDM machines and highquality EDM machines such as:HAAS,MOKRON, OKUMA, AGIE, MAKINO, Sodick etc.We can produce high precision molds andhigh quality injection molded products. Toler-ances can be up to:+/-0.001mm.

We meet all aspects of customer requirements1) Mould temperature: 60-80° C2) Barrel temperature: .front section: 220~260°CMiddle section: 290~310°CBack section: 300~320°CNozzle: 290~300°C3)Injection pressure: 60~ 70Mpa4) Injection speed: medium5) Injection time: according to the size of thepart, it is better if the part fills the mould and thesurface is basically cooled and shaped.

| Company Name | Guangdong Engineering plastics Industries(Group)Co,Ltd |

| Brand | Guangdong Engineering plastics |

| Main Product | Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc |

| Injection Machine(Double Color) | 88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T |

| Application | Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc |

| Mould Base | LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc. |

| Mould Material | 718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc |

| Moud Precision | +/-0.01mm |

| Mould Life | 100K-1000K shots |

| Mould Cavity | Single cavity, multi-cavity |

| Runner System | Hot runner and cold runner |

| Manufacturing Equipments | Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc |

| Plastic Raw Material | Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PEEK, PAI, PI, PBI,etc. |

| Color | white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc |

| Surface Treatment Tech | Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

| Product Drawings | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Lead time | 15-30 working days for injection moulds,plastic products according to quantity |

| Quanlity System | ISO 9001, RoHS Srandard, etc |

| Our Spirit | "Engineering Plastics" can be used instead of "Steel"!Science and technology will change the future!Guangdong Engineering Plastics Industries Company! |

| Other | 24 hours instant and comfortable customer service!Shipping status notification during delivery!Regular notification of new styles & hot selling styles! |

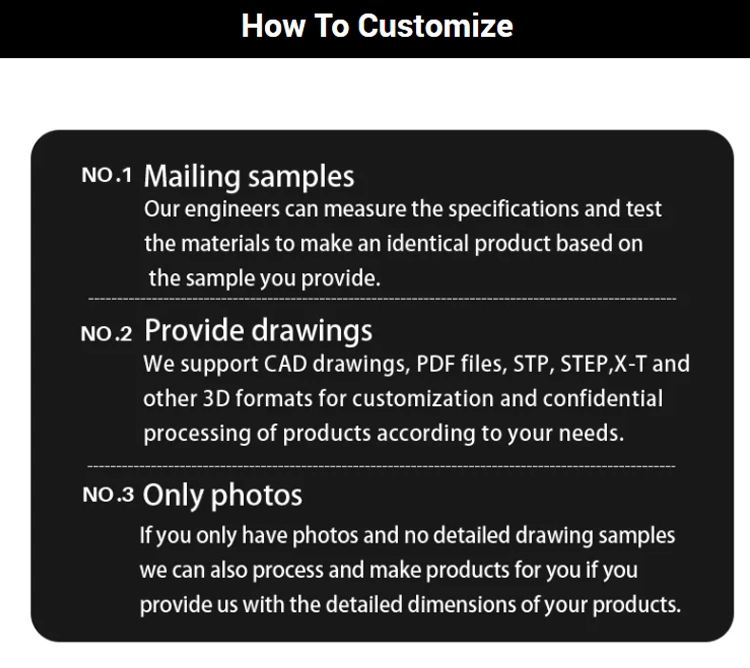

ApplicationWe have a professional engineer team to design custom parts for your needs , we also have ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you . If you have any problems or want to get the quoted price of any plastics or machined components, please feel free to contact us. Our engineers will reply to you as soon as possible.A wide range of injection mold optionsOur products cover auto parts mold, electrical appliances injection mold, medical machinery and so on. We provide products and services to more than 60 countries and regions in the world, including Europe, the United States and Southeast Asia.

Our Factory

Our factory has 100 sets of precision processing equipment, welcome to visit our factory!

One-stop ServiceOEM, ODM, Customization service,Reasonable and competitive price,Design for Manufacturability (DFM) analysis with every quote,Short Delivery Time.

Reliable mold expert 15+ years' experience, Cooperated with many world famous brands for many years, Specialize in large and complex injection mold making, One-stop service from design to production.

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Professional team

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

Client Witness

Q1. Can samples be produced?A1. YesQ2. What is the accuracy of the products processed by the drawings?A2. Different equipment has different accuracy, generally between 0.05-0.1Q3. What craftsmanship do you have for processing accessories?A3. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.Q4. What are your processing equipment?A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, moldingmachineQ5. Can you help assembling the product after it is made?A5. It's okayQ6. What certifications or qualifications does your company have?A6. Our company's certificates are: ISO, ROHS, product patent certificates, etc.Q7. Can injection products be surface treated? What are the surface treatments?A7. It is ok. Surface treatment: spray paint, silk screen, electroplating, etc.

Prev: PP ABS Tool Cabinet/Work

Next: Development Design Precision Mould PP Plastic ABS Injection Molding Processing Product Shell

Our Contact

Send now