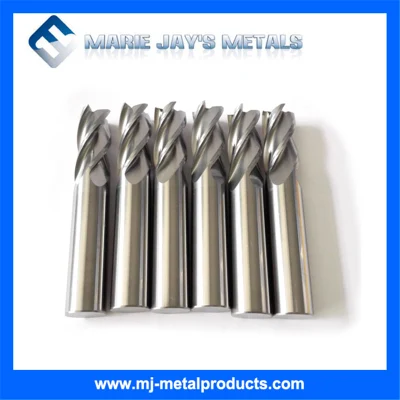

4/6 mm Three Faces Engraving Bit Advertising Wood Working Jade

Description

Basic Info.

| Model NO. | I-MCS-05 |

| MOQ | 1 PC |

| Usage | Sintered Diamond Engraving Bits for Carving Stone |

| OEM & ODM | Acceptable |

| Customized | Acceptable |

| Transport Package | Carton |

| Specification | Customized |

| Trademark | Max Cut |

| Origin | China |

| Production Capacity | 50000 PCS / Year |

Product Description

If you have any questions, please feel free to send inquiry.

Product Parameters

| Applicable Industries | Granite, Stone, Marble, Sandstone, Blue stone and Other three-dimensional Relief Work |

| Product Name | Sintered Diamond Engraving Bits For Carving Stone |

| Material | 9CrSi,SKD11/D2 ,Cr12Mov ,W6Mo5cr4v2, W18Cr4v, tungsten steel, alloy, stainless steel, HSS, inlaid alloy, etc. |

| Usage | Milling Bottom , Slotted, Hollowed-out Engraving, Line Engraving |

| Size | Customized |

| OEM & ODM | Acceptable |

| MOQ | 1PC |

Max Cut products are widely applied in various industries, such as:Corrugated Cardboard & Carton Packaging Industry, Paper Mill, Tissue& Towel converting, Plastic& Flexible Packaging Industry, Food Packaging, Tobacco Cutting, Fabric& Textile & Leather Cutting, Film& Foil Cutting, Tube Cutting, Metalworking, Wood processing, Shredder/Crusher Blade and more.Max Cut is always ready to support you the industrial cutting knives with expected quality at the best price and reliable turnaround time.Please join us for"Win-win cooperation".FAQ

Q1: Are you trading company or manufacturer?A1: Our factory is a professional manufacturer of industrial blades for more than 20years.Our blades are mainly used in: packaging, paper, rubber, optoelectronics, electronics, light industry, printing, metallurgy, and other machines.Q2: What is your blade hardness?A2: Different material has different hardness, from 48HRC to 68HRC, we can supply all of these. You can describe the use, we'll provide suitable suggestion for you.Q3. Where were cutting blades exported before?A3: Our industrial blade have been exporting to over 40 countries, including: Vietnam, Thailand, Myanmar, Philippine, Malaysia, Indonesia, India, Egypt, Emirate, Bahrain, Saudi Arabic, Israel, Russia, Lithuania, Mexico, Brazil, Argentina, Venezuela, Honduras, Korea and etc.

Our Contact